Excipients

Excipients

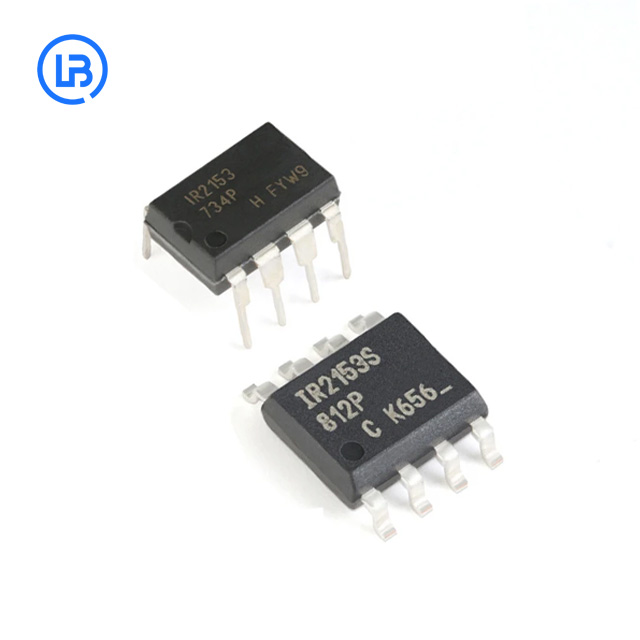

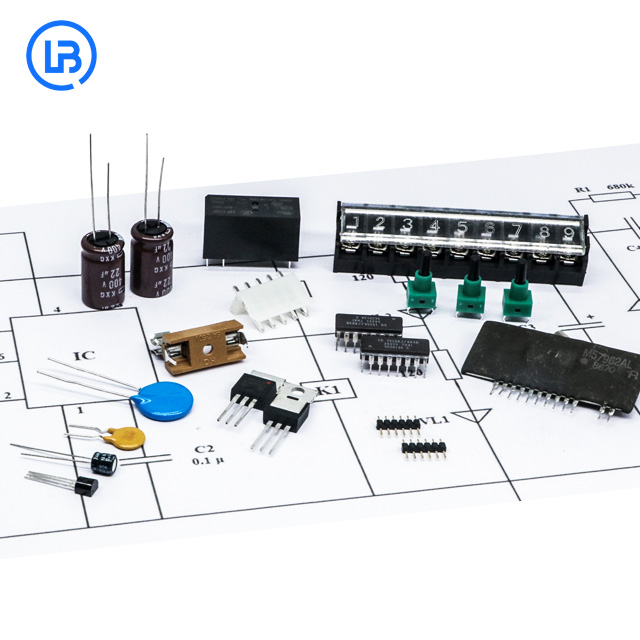

Electronic auxiliary materials are crucial components in the manufacturing of electronic products, enhancing their functionality and reliability. Conductive materials ensure proper electrical connections, while insulating materials prevent unwanted electrical flow. Thermal management materials dissipate heat, and protective coatings safeguard against environmental factors. Identification and labeling materials facilitate manufacturing and tracking.The selection of these materials is crucial, as they directly impact the quality, performance, and durability of the final product.

- Application: These accessories play an important role in household appliances, automobiles, industry, medical instruments and other fields.

- Provide brands: LUBANG cooperates with a number of well-known manufacturers in the industry to provide you with high-quality accessories products, including TDK, TE Connectivity, TT electronics, Vishay, Yageo and other brands.

Product Comparison

Model 1: 3M Polyester Film-based Electrical Insulating Tape

Polyester film

Acrylic

130°C

2.5/0.0635mm

5500V

Greater than 1×10^6 megohms

20/448 lb/in (N/10mm)

100%

1

35/3.8 oz/in (N/10mm)

-

-

-

vs

vs

Substrate

Adhesive

Operating temperature

Thickness

Dielectric breakdown/Voltage resistance

Insulation resistance

Tensile strength

Elongation at break

Electrolytic corrosion coefficient

Adhesion to steel

Color

Voltage rating

Size

Model 2: 1500 Electrical Insulating Tape

-

-

-

0.13mm

Greater than 39.37KV/mm

-

-

-

-

-

Mostly black

Same as 1300 electrical tape

18100.13mm

Product Description

| Number of floors | Single layer, double layer, 4 layer, 6 layer, etc |

| Materials | Polyimide (PI), polyester (PET), copper foil, aluminum foil, etc |

| Plate thickness | 0.1mm,0.2mm,0.5mm, 1.0mm, etc |

| Copper thickness | 18μm,35μm,70um, 105μm, etc |

| Minimum cable width/spacing | 0.1 mm / 0.1 mm, 0.05 mm / 0.05 mm, etc |

| Minimum hole size | 0.3mm,0.5mm,0.8mm, etc |

| Aspect ratio | 1:1,2:1,4:1, etc |

| Maximum plate size | 300mm×300mm, 500mm×500mm, etc |

-

Phone

-

E-mail

-

Whatsapp

WhatsApp

-

Top